Welcome to Jain Irrigation Systems Ltd.

Blog at Jains - HOW CHANGES IN AGRONOMY Help Micro-irrigation Technology to Enhance Crop Performance

Dr.P.Soman, Chief Agronomist, (Global), JAIN IRRIGATION SYSTEMS LTD.

Changing the method of irrigation from surface flood or even furrow guided flow to micro irrigation (MI) is found to improve yield of the crop by 15-25 % in cereals, 25-40% in pulses and oil seeds, 50-70% in vegetables, and 80-100% in fruits. And in sugarcane yield often increased by 100- 160%. These inferences are from observations made from large number of farmers’ fields over the last 35 years by the author. In fact, this enhanced crop productivity is one major factor that helped in the farm level acceptance of MI in India and giving the country the pride of place – Country with highest area under drip irrigation and second highest area under sprinkler irrigation (as on 2021 June) in the World. How could a change of irrigation method improve yield? Very simple but common query. Let us discuss.

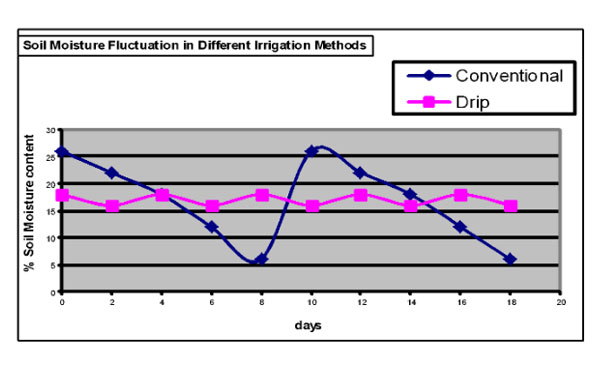

In drip irrigation soil wetness is maintained at an optimum level throughout the crop duration by scheduling irrigation based on ETP. There will not be cyclical recurrence of water logging (excess soil moisture) or drying of the soil (inadequte soil moisture) during the crop life as soil would experience in furrow or flood irrigation (Fig 1). The cyclical drying and wetting scenario affects the growth rate of the crop- both dry and water logged soil impede growth rate. Hence the crop will not be achieving its yield potential under conventional irrigation method.

Fig 1. Soil wetness patterns in drip and flow irrigated situations.

In addition to the moisture related factor, other factors those act concomitantly with change of irrigation method- fertigation , change in crop geometry, changes in population size, changes in land and soil management, changes in crop architecture management (pruning and training) etc. induces more positive factors for crop growth and development. All these are aimed to produce more yield and quality of produce.

This lecture would high light the deliberate changes the grower would make in Agronomy and crop management those that will help in harvesting yields closest to the potential yield of the crop.

Individual cases of high-tech interventions

The following are actual cases where high- tech cultivation practises were introduced after considerable R&D and field level demonstrations at Jain Research farm. These technologies are taken up by farmers from different parts of the country whole heartedly. Some among them have become entrepreneurs themselves.

Onion

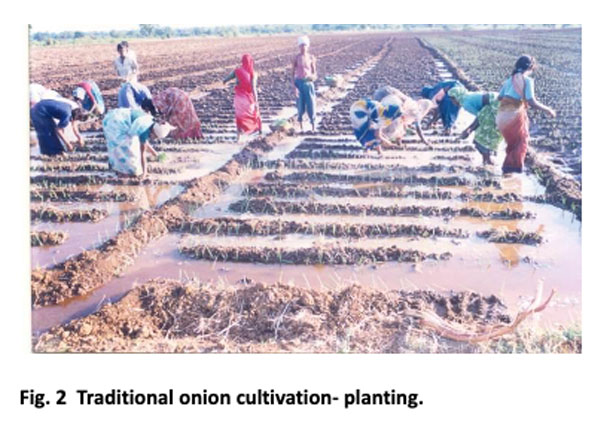

Onion is one of the important vegetable crops grown in India. In terms of area, India ranks first in the world with over 480,000 ha. Globally, the country occupies the second position after China in onion production with a production share of around 14 per cent. Productivity, however, at around 13 t/ha, is much lower than the world average of 17.3 t/ha.

Onion is produced in several states in India, with Maharashtra being the leading producer accounting for about one-fourth of the country’s onion production. India largely produces red onions used as fresh produce in the domestic market. White onions (used for dehydration) are grown on commercial scale only in the states of Maharashtra and Gujarat and that too only in a few districts. Red onions are not suitable for dehydration mostly due to low solids, low pungency levels and high reducing sugars. The local white varieties available in the country are low in solids < 12.5% TSS, prone to premature bolting during Rabi (30-40% bolting) and hence not suitable for dehydration

Onions for processing focus on high yields and other desirable processing characteristics such as high total soluble solids content, snow-white colour, narrow stem-base, bolt resistance during bulb crop etc.. The woody stem of the stalk of the umbel reduces the quality of the dehydrated product. Thus the company took up focused R&D to breed for High TSS and bolting resistant white onion.

Seed production

Cultivar Cv. JV12, was selected for further detailed investigation. Extensive trials were carried out during the subsequent four year period on water, fertilizer, disease and pest management of JV 12 variety. Based on the results, a package of agronomic practices has been standardized. The R&D team then went ahead to produce the seeds of this variety within the country under our own conditions and management. Quality seeds of the elite selection JV12 are being produced on commercial scale since 2000 in Himachal Pradesh to get cool short day periods.

High-tech precision farming practices

The introduction of hi-tech precision farming technology in onion cultivation has been a great success. The company was successful in revolutionizing the farming practices with an objective of ensuring supply of quality produce. The high tech practices were introduced in 2001-02 with the principal objective to enhance productivity and uniformity with better agronomical practices and also to improve the quality of onion bulbs.

Under contract farming, the high-yielding onion seeds are distributed to the registered growers and the seeds are sown and transplanted in the farmers field by the farmers using their own resources. Company’s R&D, extension wing help the cultivators from time to time through frequent field-visits, guidance and input supplies.

An important feature of the planting material provided by the company is the high germination rate about 80-85%.

Availability of Production Technology/Equipments and their Adoption

A prescribed set of practices were adopted by the contract farmers, specifying the fertilizer requirements and spraying time. Also, they have educated farmers about cropping patterns. After working with the company they have shifted to rotation of onion with legumes. Two key advantages from growing legumes is nitrogen fixation which helps to enhance soil fertility. Also, legume cycle is shorter and more appropriate for planting onions. The farmers feel that overall, they have benefited from the legume, onion rotation. The overall benefits of soil fertility and income is higher in legume – onion crop rotation. The productivity for the farmers working with the package were between 10 tons to 14 t/acre (average productivity 12 t/acre), whereas the average productivity in the case of traditional production is around 5-7 tons/acre.

An important aspect of technology is that the farmers working with JISL are using drip irrigation. Use of micro-irrigation technology enables higher productivity by ensuring adequate availability of water. In the long run, the farmers are using much less water than the traditional flood irrigation approach, which is better for the environment, as well as ensures lower cost and higher productivity for the farmer. If the farmers cannot pay for irrigation upfront, the company either arranges a loan for them, or provides drip irrigation on credit, for which the cost is deducted from the sales of onions.

Farmer Earnings:

The gross margin for the farmers working with the technology package and selling for processing is much higher than the margins for farmers selling to the traditional market. The cost of production (variable cost) for farmers working with the high tech practises is Rs. 17,800 per acre, whereas the same is Rs. 11,800 per acre for the farmers following traditional practises and selling to the traditional market. The main difference is due to the higher costs for irrigation system and associated water costs.

There is however, a significant difference in the productivity levels of both the groups. While the average productivity of the farmers selling to the traditional market is app. 7t/acre, it is almost twice at 12t/acre for the contract farmers with drip irrigation.

The High tech components in Onion production;

• High quality seed with high germination percentage

• Soil surface management –bed and furrow

• Change in Crop geometry and plant population

• Drip irrigation and fertigation

• Pest and disease monitoring by qualified extension workers

• Timely pest management

• Association of farmers with a Processor

• Processor assuring an MGP and supporting farmers

• Harvest and Post Harvest management under technical supervision.

• Technical support for rotation crop –selection and cultivation

Banana

The objective is enhancing the productivity of Banana through Tissue Culture technology and precision farming.

Banana (Musa paradisiaca) is one of the most important staple food crop for millions of people in developing countries. It is a parthenocarpic fruit and therefore renders them sterile and unable to produce viable seeds. Owing to this condition, there is no other option except to resort to vegetative method of propagation using suckers, which is commonly known as "corm". The major disadvantages of using suckers for vegetative propagation, is the lower yields, longer crop duration (14-15 months for one crop), carry- over of disease and pests etc. To overcome these constraints in-vitro micro-propagation of banana under stringently controlled aseptic conditions in the laboratory is the most ideal way to produce high quality planting material.

As far as tissue culture technique is concerned, the key issues relate to adoption of a very precise protocol for the micro-propagation of banana, followed by primary and secondary hardening that it renders the tissue-raised plants to perform well in the field adapting to the local soil and climatic conditions. This is perhaps the most important criteria for developing disease-free and true-to-type plantlets with higher farm yields and excellent quality that can be accepted world-wide.

Of all the banana varieties tested, Grand Nain (belonging to the dwarf Cavendish group) proved to be the most suitable one. This introduced variety, owing to its quality attributes, was found to be ideal both for processing as well as for fresh fruit export.

An R&D project was set in motion for developing and standardizing the technology for production of high quality Tissue Culture planting material and testing and developing an appropriate cultivation technology.

In Jalgaon district of Maharashtra, banana is grown in an area of approximately 48,000 hectares and is therefore aptly termed as the ‘Banana Bowl of India’. This district produces approximately 76% and 18% of Maharashtra’s and India’s banana production, respectively. The area suffered low yields of banana due to poor quality planting material, uneven and off- type suckers and high incidence of virus diseases. Therefore, the main objective of the project was to transform Jalgaon district’s productivity to a higher level.

Acceptance by Banana Growers :

The Tissue cultured banana plants and the package for cultivation have received an overwhelming response from the farms not only in Jalgaon district, but from different states of India as well. It is reflected in the ever increasing demand for the TC plants, which currently is around 150 million per year.

The various components of the high-tech package were;

• Elite uniform virus free planting material

• Intervention in Land preparation, crop geometry

• Introduction of drip and fertigation technologies

• Interventions in Crop management till harvest and packing

• A precise sucker management technology and opportunity for ratoon

• Assistance in PHM and technical support for packing house and ripening facilities

• Training and guidance to farmers.

• Introduction of banana puree technology in commercial scale for value addition.

Table 1. Key differences between traditional sucker planting vs elite TC banana plants:

Traditional Sucker planting |

Elite Tissue Culture Banana plants |

Haphazard Planting |

Defined Crop Geometry |

Flood Irrigation |

Drip Irrigation |

Broadcasting Solid Fertilizers |

Fertigation |

Yield per plant is 13-15 kgs |

Yield per plant is minimum of 30 kgs. |

High disease incidence |

Low disease incidence |

Long gestation crop period |

Short gestation crop period |

Performance

Hi-tech farming also generates employment opportunities in the villages as it needs large number of farm hands for harvesting, loading, transport, unloading etc. Employment is generated for agriculture technicians who assist the farmers in maintaining their equipments/gadgets/systems of irrigation & fertigation stations etc.

Economic impact of TC Banana cultivation among rural farmers

The Tissue Culture plants that we give have consistently provided better yields to the farmers, from a banana bunch of 15 kgs (with conventional planting material) to almost 25 kgs on an average (with tissue culture planting material). This has improved not just the overall yields but has reduced the growing period giving farmers higher returns in a shorter period of time. With the high quality tissue cultured plants farmers they are able to harvest 3 crops in a period of 30 months as compared to only two crops in with conventional sucker planting in same period.

Drip irrigation and fertigation augments the yield increment. Some control can be exercised on maturity period affording advancing /postponing harvesting to fetch good prices in the market. Banana processing adds value to the Banana fruit produced by farmer.

Tissue culture plants increased productivity to two and half times with than the sucker planting material. Total revenue generation and net profit from one planting cycle (i.e. 30 month) has gone to Rs 3.06 and 1.80 lakh per acre, respectively as compared to Rs 1.25 and 0.52 lacs per acre, respectively in conventional cultivation.

Currently, the TC planting material production is extended to several other varieties- Poovan, Njali Poovan, Monthan, Nendran , Chenkathali etc.

Mango

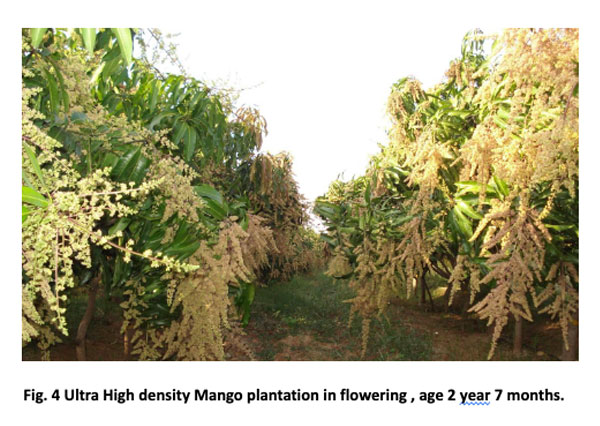

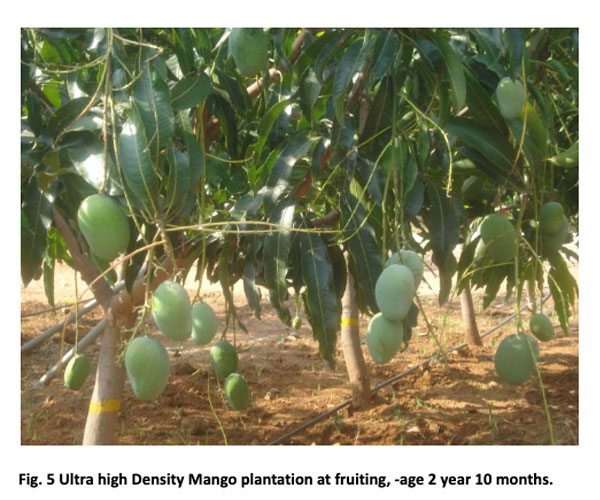

India produces world’s highest tonnage of mango (13.73million tones from an area of 2.15 million ha) with an average productivity of 6377 kg/ha. Mango, so far has been grown either as a crop with least management efforts and without inputs like irrigation, fertilizer etc. Therefore the productivity is low rendering it un-remunerative. Mango cultivation can be revolutionized by the adoption of Ultra High Density Plantation (UHDP) and associated practices. Jain Irrigation Systems Ltd (JISL) heralds a new era where mango becomes a quick, high, stable yielding, sustainable cash crop. With increased demand of mango, shrinking land availability, increasing the productivity per unit area is imperative. Besides, effective utilization of natural resources like water, nutrients, fuel, etc. is also important. Hi-tech cultivation techniques like UHDP combined with micro irrigation, fertigation, crop regulation, proper training and pruning may play important role in achieving these objectives. JISL has established commercial UHDP orchards in its R&D farms and their performance have been found to be very promising. There is immense scope to increase the productivity to 5-12 t/ac depending on varieties by using UHDP and other improved agro-techniques.

Mango tree is believed to have evolved as a canopy layer species in the tropical rainforest of south and south-east Asia. Mature specimens can attain a height of 30 m and can survive for more than 100 years. The root system consists of a long, vigorous taproot and abundant surface feeder roots. Both male and perfect flowers are found within a single inflorescence; the pistil aborts in male flowers. The ratio of male to perfect flowers is strongly influenced by genetic, environmental and cultural factors. Flowers are cross-pollinated by flies and honey bees.

Mango is well adapted to tropical and subtropical climates. Though Mango can grow up to 1400 m altitude, commercial mango orchards are raised at places upto 600m altitude. Its growth and fruiting are influenced by temperature, rainfall, wind velocity and altitude. Annual mean temperature ranging from 21°C to 27°C is ideal for successful crop, though it can grow in a temperature range of 5 to 44° C. Higher temperature at fruit development enhances fruit size and quality. Mango can perform well in areas with average annual rainfall of 250 to 2500mm. However, frequent rains and high humidity will result in incidence of pests and diseases.

Cultivation Practices for Ultra High Density Plantation (UHDP)

Mango can be grown in a wide range of soils except clayey or extremely sandy or rocky calcareous, alkaline or water logged soils. It prefers a soil pH of 6.5 to 7.5. For successful establishment of orchard, soil depth of 2.0 to 2.5 m is required. Soil amendments may be used to correct the soil to get required pH. Soil test is prerequisite for deciding quantity of soil amendment.

Mango varieties

Field experimentation in Jain R&D farm were conducted with Alphonso, Ranta and Sindhu and several other varieties of South and Central India. Based on our experience and various scientific reports, we believe that the most varieties in India can be grown successfully under UHDP. As the Cultivation Practices are very intensive, we prefer to recommend high value varieties.

Table 2. Mango varieties for UHDP

State |

Varieties |

Andhra Pradesh |

Alphonso, Alampur Baneshan, Banganapalli, Totapuri (Bangalora), Mallika |

Bihar |

Bombai, Himsagar, Langra, Chausa |

Goa |

Fernandin, Mankurad |

Gujarat |

Alphonso, Kesar |

Karnataka |

Alphonso, Bangalora, Neelum, Mallika |

Madhya Pradesh |

Alphonso, Kesar, Ratna |

Tamil Nadu |

Alphonso, Banganapalli, Imampasand, Totapuri (Bangalora), Neelum |

Uttar Pradesh |

Bombay Green, Dashehari, Langra, Lucknow Safeda, Mallika, Chausa |

Under UHDP, Mango is planted at 3m x 2m which accommodates 674 plants per acre. Pits should be marked at 3m x 2m before pit digging and pits of l x l x l m are to be dug at marked places. Alternatively one meter deep and one meter wide trench can be prepared at every three meter. The pits should be allowed to wither for some weeks before filling with mixture of planting media. The media consists of 40-50 kg native soil, 0.5 -1.0 kg Single Super Phosphate (SSP), 0.25 kg neem cake, 20 kg compost or 10 kg vermi-compost and 10-15 g of Thimet or 20g Furadon. Plantations are to be raised by using grafted saplings. Plants must be procured well before planting. While planting, soil around each graft should be pressed well.

Epicotyl grafts or soft wood grats are recommended for UHDP as the training of the tree starts at a very early stage itself. The ball of earth around the base of the graft should be retained intact and the graft joint should remain just above the ground level.

Drip irrigation should commence after planting. The newly planted grafts are to be supported by a bamboo stick to avoid damage by wind. Similarly these are protected from desiccating winds by shade crops like sunhemp raised around the sapling and which can be cut and used as a mulch later.

The critical components of UHDP technology is the management of inputs: irrigation water and fertilizer and besides the canopy management. These two inputs are provided through drip irrigation system. In several states in India, mango is not considered as an irrigated crop. By adopting the recommended practices, the farmer would be changing from subsistence level to a cash crop situation. But to achieve this he should adopt the technology wholly and not in parts.

Table 3. Crop water requirement of Mango planted at 3 x 2 m crop geometry

Month |

Evaporation, mm |

Water Requirement Lt/plant/day |

|||

1st yr |

2nd yr |

3rd yr |

4th yr onwards |

||

Jan |

2.87 - 40.60 |

0.5 - 0.75 |

2.0 - 2.6 |

4.0 - 5.8 |

7.0 - 10.3 |

Feb |

3.38 - 5.90 |

0.75 - 1.0 |

2.5 - 4.1 |

6.0 - 9.3 |

10.0 - 16.5 |

March |

3.79 - 7.29 |

0.75 - 1.3 |

3.0 - 5.3 |

6.5 - 12.0 |

11.5 - 16.4 |

April |

6.69 - 8.38 |

1.3 - 1.5 |

5.0 - 6.5 |

11.3 - 14.0 |

20.0 - 25.0 |

May |

7.54 - 9.32 |

1.5 - 2.0 |

5.8 - 7.0 |

13.0 - 16.0 |

23.1 - 28.0 |

June |

5.97 - 7.45 |

1.0 - 1.2 |

3.5 - 4.5 |

7.5 - 10.0 |

13.0 - 23.1 |

July |

4.24 - 7.47 |

0.5 - 1.2 |

2.0 - 4.8 |

4.5 - 10.7 |

8.0 - 19.0 |

Aug |

3.22 - 7.84 |

0.5 - 1.2 |

1.5 - 4.8 |

3.5 - 10.8 |

6.0 - 19.2 |

Sept |

3.57 - 7.78 |

0.5 - 0.6 |

1.0 - 2.2 |

2.5 - 4.9 |

4.0 - 8.7 |

Oct |

4.42 - 7.47 |

0.4 - 0.5 |

1.5 - 2.0 |

2.2 - 3.0 |

3.9 - 5.0 |

Nov |

3.48 - 3.84 |

0.4 - 0.5 |

1.6 - 2.0 |

3.5 - 4.0 |

6.2 - 6.5 |

Dec |

3.15 - 3.90 |

0.4 - 0.5 |

1.5 - 1.6 |

3.5 - 3.6 |

6.0 - 6.5 |

Average |

4.65 - 6.02 |

0.8 - 1.0 |

2.8 - 3.3 |

6.3 - 7.5 |

10.8 - 13.3 |

Crop water requirement will vary according to the location. The table serves only as indicative. |

|||||

For the bearing trees (3rd year onwards) irrigation to be given at survival level during September 3rd week to October to induce flowering (stress period). The rainfall events are very erratic and therefore not adjusted on a daily basis. The general recommendation is that if rain fall exceeds 10mm in any one day, suspend drip irrigation for the next 2 days.

The online drip system is found to be more suitable for Mango. The drip laterals are spaced at the relevant row spacing. Each tree is provided with one dripper of 4lph during initial two years and 2 drippers of 4lph from 3rd year. When 2 drippers are installed they should be placed 45cm away from the trunk.

Application of fertilizer

The recommended fertilizer dose for UHDP Mango in soils having medium nutrient content is given below. Estimation of fertilizer requirement should be based on soil analysis .

Table 4. Fertigation schedule for UHDP Mango (to be applied at weekly interval)

Fertigation Schedule and Quantity (kg/dose/acre) |

||||||

Age |

Month |

Number of Doses |

Urea |

H3PO4 |

MOP |

MgSO4 |

1yr |

July-Sept |

12 |

1.4 |

0.5 |

0.8 |

0.000 |

Jan-May |

20 |

1.7 |

0.6 |

0.9 |

0.000 |

|

2 yr |

July-Sept |

12 |

2.7 |

1.2 |

2.3 |

0.278 |

Jan-May |

20 |

1.6 |

0.7 |

1.4 |

0.167 |

|

3 yr |

15 June-Aug |

12 |

4.5 |

2.3 |

3.5 |

0.555 |

Sept |

4 |

1.4 |

1.2 |

3.1 |

0.000 |

|

Jan-May |

20 |

3.2 |

1.2 |

1.5 |

0.333 |

|

4 yr onwards |

15 June-Aug |

12 |

7.2 |

3.5 |

4.6 |

0.833 |

Sept |

4 |

2.2 |

1.7 |

4.2 |

0.000 |

|

Jan-March |

12 |

5.1 |

1.7 |

3.2 |

0.833 |

|

• If chloride injury is found or if the water contains high chloride then MOP should be replaced by Potassium nitrate or sulphate.

Training & Pruning

When the plant height reaches 45-60cm the terminal bud should be pinched at 5-6 cm below the apex to encourage growth of auxiliary buds. After the growth from auxiliary buds 2-3 vigorous shoots are to be retained in different directions at 15-20cm interval which will develop as primary branches.

After 4-6 months growth of primary branches, they should be headed back at 45-60cm length to allow further growth of 4-5 secondary shoots on each branch, which in turn will form tertiary shoots in due course. Ultimately the tree will present a dome shaped hedge.

Pruning is very essential and critical operation of UHDP to maintain fruiting shoots and contain the canopy. Pruning must be completed as soon as possible after harvest preferably before 15th June in Central and Southern India. Tertiary branches have to be headed back in such a way that the plant height can be maintained at 1.5 m and having 10-15 tertiary shoots. Excess tertiary shoots have to be thinned out to avoid overcrowding. Cut ends to be applied with Bordeaux paste or 2% Copper Oxychloride (COC) suspension. About one month after pruning thinning of newly emerged shoots is essential to avoid excess shoots and overcrowding. On each tertiary shoots 3-4 new shoots are to be maintained. Dried panicle along with 2-3 leaves and dried shoots / branches must be removed at the time of pruning.

Crop Regulation

Some varieties of mango is prone to alternate bearing. However bearing can be regulated by UHDP management combined with pruning and chemical treatments. In recent years, application of Paclobutrazol (PBZ) has shown positive response. PBZ should be applied from the third year onwards, in the month of September (in Central & South India) or October (in North India).

Rejuvenation Pruning and Top Working

By rejuvenation we can improve productivity of old orchards. Combined with top working, improved or new variety can be grafted in existing trees. During this operation an existing conventional orchard can be converted to UHDP by planting additional saplings. The old and non- productive branches are cut at the base or the origin. Leave one branch to allow for survival growth and cut all other branches at the point of origin. This is best done after the fruiting season (in central and southern part of India) or at the end of winter (in northern India) which will allow for sprouting after 30-45 days. Apply COC paste on the cut surface to prevent fungal entry into the trunk. Drip irrigate as per schedule. Rejuvenation and top working will make the old tree juvenile again and help in canopy management of the orchard. Once top working is practiced, inter cropping can once again be practiced in the orchard.

Benefits of UHDP and associated technologies

• Increases productivity upto 2-3 times.

• Reduces orchard gestation period to three years as compared to conventional orchards ( 7-9

years)

• Makes orchard crops as profitable as other cash crops

• Reduces water used for irrigation upto 50%

• Increased fertilizer uptake by plants when fertigation is practiced.

• Suitable for small, medium and semi-large farmers as its management intensive and yields good quality fruits which can get better market price.

• It makes sensible bankable project to offer financial support due to assured high early returns.

Table 5. Advantages of Ultra high density (UHDP) Mango planting

Particular |

Planting Type |

||

Traditional (40 trees /ac) |

Medium Density (200 trees/ac) |

Ultra High Density (674 trees/ac) |

|

Gestation Period (years) |

10-12 |

5 |

3 |

Duration to reach full potential (Years) |

15 |

8 |

6 |

Yield potential |

Medium |

High |

Very High |

Orchard management activities : |

|||

Pruning |

Very difficult |

Manageable |

Easy |

Spray operation |

Difficult |

Manageable |

Easy |

Spray efficiency |

Very low |

Fairly high |

High |

Harvest |

Very difficult |

Possible |

Very easy |

Control on fruit quality |

Impossible |

Possible |

Easy |

Expected yield at maturity (t/ac) |

|||

1.High volume varieties |

4-5 |

7-8 |

10-12 |

2.Low volume varieties |

1.5-2.0 |

2-3 |

4-5 |

Expected income/yr ( lakh Rs/ac) |

|||

1.High volume varieties (@Rs 8/kg) |

0.32-0.40 |

0.56-0.64 |

0.80-0.96 |

2.Low volume varieties (@Rs15/kg) |

0.23-0.30 |

0.0.3-0.45 |

0.6-0.75 |

Commercial orchard life (years) |

Up to 50 |

30-35 |

20-25 |

The cost of setting up an UHDP plantation is Rs 80,000.00/ac as against 50,000.00/ac for traditional (40 trees/ac) and 60,000.00 /ac (200 trees/ac) and the yearly recurring expense comes to Rs 30,000.00/ac in the UHDP (Soman, 2009). The actual yields harvested in UHDP in year 4 and 5 are highly indicative of the projections above; a high volume variety like Ratna yielded 8.4 and 9.0 t/ac and a low volume cultivar, Alphonso yielded 1.7 and 2.4 t/ac.

Conversion of conventional garden into UHD plantation

• Top work the existing old trees. Allow regrowth in a controlled canopy fashion.

• Plant new saplings in the inter row and intra-row space to get a final spacing of 3 m x 2 m.

• Train and prune the trees old and new as per a schedule.

• Provide drip fertigation to all the trees.

High-tech components in Mango cultivation

• Quality planting material –epicotyl grafts

• Changing Crop geometry and population

• Training of tree at very early stage to enforce a tree architecture

• Intensive pruning after harvest to contain the canopy to 1.5 m height every year

• Drip irrigation and fertigation

• Enforcing a stress period

• Hormone application to convert alternate year bearing to annual bearing.

• Fruit pruning to maintain optimum fruits per tree

• Hand harvest for quality assurance

• Post Harvest Management guidelines

• Value addition opportunity by pulping/diceing

Apart from these crops , the discussion would include such interventions in several crops including rice, wheat , maize , pulses and ecologically restricted crops like saffron and apple too.